Test “block” features.

Andrew “Bunnie” Huang has written a book describing the realities of launching new products in China. It has a broad scope, covering engineering, business practices, and cultural norms for China.

The Hardware Hacke (Adventures in Making & Breaking Hardware)

by Andrew “bunnie” Huang

No Starch Press

If you are involved in management, engineering, accounting, support, or most any other area of high-tech electronics, you should read this book, especially sections 1 and 2. The author offers great insight and advice on bringing designs into production, particularly when production is moved to China. The first five chapters cover development and mass production of an open source design internet data “appliance” called “Chumby.” Here are some of the topics covered:

If you are involved in management, engineering, accounting, support, or most any other area of high-tech electronics, you should read this book, especially sections 1 and 2. The author offers great insight and advice on bringing designs into production, particularly when production is moved to China. The first five chapters cover development and mass production of an open source design internet data “appliance” called “Chumby.” Here are some of the topics covered:

With advances in LED lighting, this TaoTronics desk lamp looked like it would fit my needs, which were:

The most common complaint in the lower rated (1-3 star) reviews on Amazon cited functional failure of the light or the touch-control panel (used to vary brightness), so when I received the lamp, the first thing I did is set it up and run it through several on-off cycles, ranging from a few minutes to 24 hour on, for about 4 days.

The most common complaint in the lower rated (1-3 star) reviews on Amazon cited functional failure of the light or the touch-control panel (used to vary brightness), so when I received the lamp, the first thing I did is set it up and run it through several on-off cycles, ranging from a few minutes to 24 hour on, for about 4 days.

> Link to full article and video

In over 25 years of electronics troubleshooting on a wide variety of analog and digital equipment, some of it cutting edge, I have concluded that a majority of failures were due to failed connections. That is, components such as switches, plugs and jacks, crimped wire terminals, circuit board conductor fabrication, and solder joints failed more often than the components they connect. In the 21st Century (I like saying that) connectors, other than optical systems, still rely on old technology: mechanical contact between conductors.

The good news is that Non-mating Connectors (NMCs) use a totally different technology to transfer signals and power, and hold great promise for increasing the reliability of electronic equipment. Read more..(in Reliability section)

This blog has a section devoted to products of poor quality &/or design (see Quality Fail), but this post stands alone for an exceptional failure which could endanger people and property.

The product is a large, standalone propane patio heater manufactured by Shinerich Industries in China. They are marketed in the U.S. under names such as “Charmglow”, “Fire-Sense”, “Blue Rhino,” and are commonly sold in “big box” stores and on Amazon.

In March, 2014, a gust of wind (est. 15-25 mph) blew the top reflector off! The metal screen had totally failed and broken apart. It was the only support for the hood. The metal was degraded to the point where it crumbled like a potato chip.

Play this video to see more details:

The heater was only used 10-15 times, and appeared to be in good condition, with only minor exterior corrosion. The unit was not being used at the time, so there was no fire danger.

Had it been on, with people gathered around, they may have been seriously burned by red-hot metal pieces. Even with the unit flame off, the large, heavy reflector could have injured someone or gone through a window. It flew about 15 feet away from the base, but not toward the house–we were lucky.

The metal screen was clearly not suitable for use. As a comparison, I tested a similar unit (nearly 7 yrs. old) owned by a neighbor, and the screen material was strong–it withstood light hammer blows with no bending or cracking.

In early April, I reported this failure to the manufacturer, to CSA (they certify these), and to the U.S. Consumer Products Safety Commission. I have kept samples of the metal screen, and offered to submit them for forensic investigation. CSA has not responded to my reports or offer of samples of the screen. I believe part of this is because there were no injuries or other damage, and CSA knows that the manufacturer subverted or avoided the surveillance in the factory to use a substandard metal, not certified for use in a propane flame environment. In other words, “CSA Certified” is no guarantee of a safe product. But again, “Nobody got hurt and you don’t have any damages to claim,” is probably the main concept that applies here.

On Amazon.com, there was a similar report involving a 2 yr. old unit (ours was approx. 4 yrs. old), but I have not been able to get any more details. This is disturbing, because there may be hundreds of these waiting to fail. In the 21st century, there are certainly high quality metals that have been designed for this use, but Shinerich did not use such a metal on this particular unit. We now have a large large, useless heater that would be cheaper to replace than repair. If there is any news on this situation (contact from CSA, etc.), I will create a new post.

The IEC60601 standard isn’t simple to understand. Experienced engineers not trained in this standard may present sound designs but still have problems with certification. There are many grey areas when it comes to component certifications. The better you understand the standard, the more quickly (and cheaply) you can get the product certified. Here are ten pitfalls I have encountered as a Product Safety Engineer:

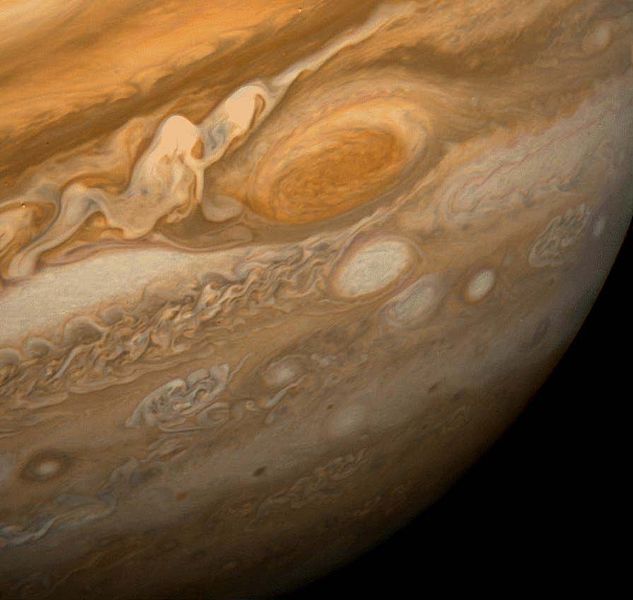

Early in the mission, Voyager 1 sent this image of the Great Red Spot on Jupiter.

The Voyager 1 Spacecraft, launched by NASA on Sept. 5, 1977, is nearing the edge of our solar system. It has traveled over 18 billion kilometers, and continues to function as designed. This is a case where quality exceeded expectations. More on Quality Excellence.